Product introduction:

ZLB type rotary granulator is mainly used in food, powder, chemical, solid beverage and other industries, the stirred material into the required particles, suitable for high viscosity materials. The machine is made of stainless steel where the contact part with the material, beautiful appearance, reasonable structure, high pelletizing molding rate, beautiful particles, automatic discharge, avoid the particle damage caused by manual discharge, and suitable for flow operation.

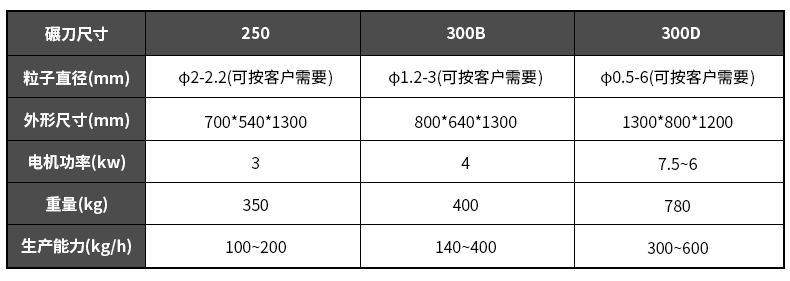

Technical parameter:

Working principle:

The material in the feed mouth is cut, compressed and extruded through a high-speed rotating blade and screen to form particles of a certain shape and size. In the granulation process, the material is subjected to repeated shearing, compression and extrusion, gradually forming particles, and filtered through the screen, the oversized particles are discharged, and finally the particles that meet the requirements are obtained.

Product characteristics:

Low energy consumption, low noise, high output, when the output can reach 500kg, easy operation, easy maintenance, the use of roller granulation, drum disassembly, easy cleaning, mechanical transmission system is all closed in the body, the use of stainless steel material, in line with the industry demand standards.