Product introduction:

The high-speed mixer is made of powder material and adhesive in a cylindrical container by the bottom mixing slurry fully mixed into wet soft material, and then by the side of the high-speed grinding paddle cut into uniform wet particles.

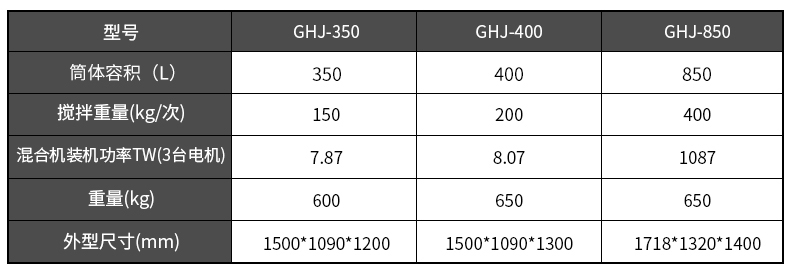

Technical parameter:

Working principle:

GHJ vertical high speed mixer is composed of bottom feed pulp and high speed crusher pulp. The feed blade pulp continuously feeds the bottom material upward along the wall of the cylinder.

The high speed crushing pulp breaks up the material sent by the pulp. Make the material circulation form a vortex shape, and achieve the purpose of mixing the material evenly in a short time.

Product characteristics:

GHJ vertical high speed mixer is a mixer developed by our company with domestic and foreign technology. Its main characteristics are as follows.

● Due to the action of centrifugal force, the bottom feed blade slurry continuously feeds the bottom material up along the wall of the cylinder, and the upper material falls down from the center, so that the material circulates into a vortex shape.

● The bulk material sent by the feed leaf pulp is broken up by the high speed crushing pulp.

● Due to the high-speed rotation of the above two kinds of pulp, the material can be mixed evenly in a short time, and the mixing speed and uniformity are non-granular in the middle of the mixed material that other mixers can not achieve, and the mixing uniformity is more than 90%.

● Open the discharge valve, the discharge speed is fast, the equipment is easy to clean.

● The material contact point of the machine is made of stainless steel, which will not cause volatilization, deterioration and loss of materials during the mixing process.

● The machine is suitable for mixing dry and wet materials of different proportions, especially for mixing chicken essence, pharmaceutical powder, beverage powder and other complex mixed materials.